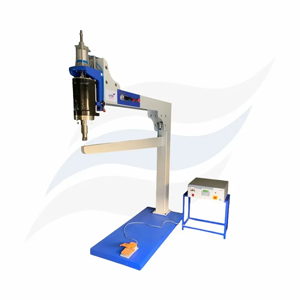

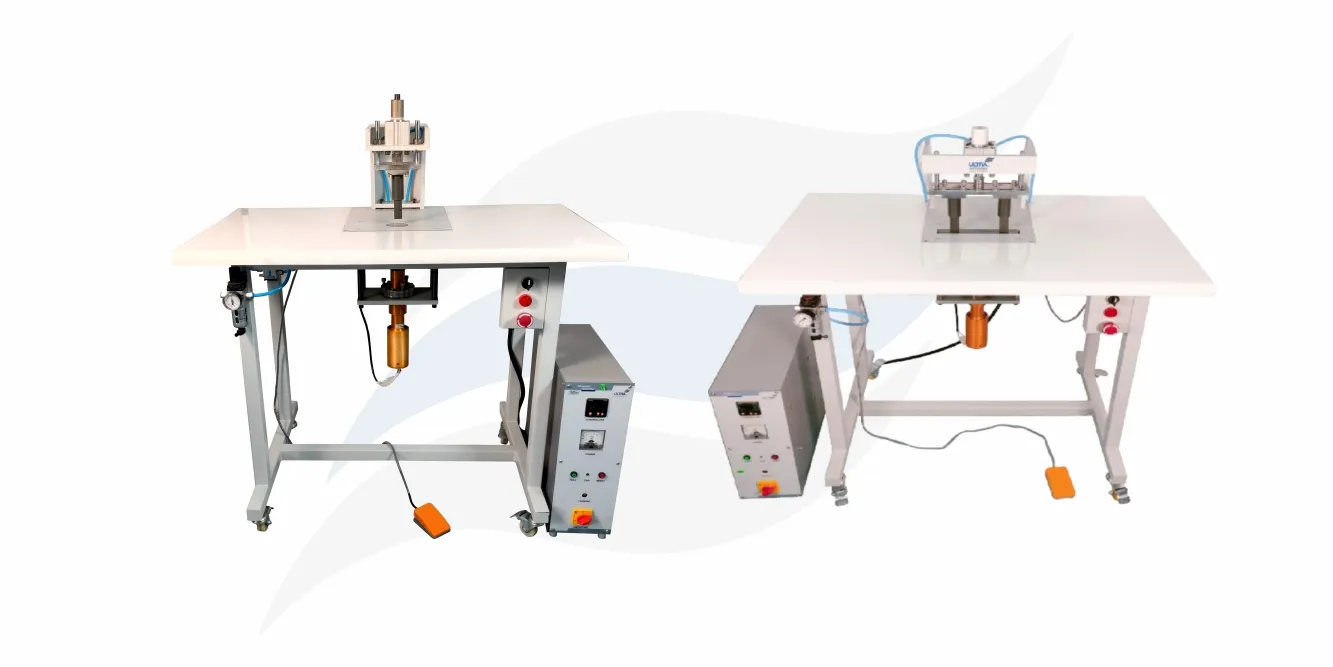

ULTRAAUTOSONIC innovates the Ultrasonic Spot Welding Machine, which is used in the automotive, electronics, medical, home appliance, non-woven, Stationary, and packaging industries. An ultrasonic spot welding machine is a device used in various industries, where precision bonding of materials is required. This technology employs high-frequency ultrasonic vibrations to create heat through frictional forces that melt and join materials.

✔ ULTRA-SWM 1 20-1000

✔ ULTRA-SWM 2 20-1500

| Machine Type | Single Spot | Double Spot | ||

|---|---|---|---|---|

| Frequency (kHz) | 20 kHz | |||

| Power (Watt) | 1000 Watt | 1500 Watt | ||

| Actual Weight | Approx. 52 kg | Approx. 60 kg | ||

| Actual Size (L x W x H) | Approx. (997 X 605 X 1169) mm | |||

| Packaging Type and Size | Wooden Box and Approx. Size (1144 X 752 X 1316) mm | |||

| Operational Requirement | ||||

| Input Power Supply | AC 230V 50/60Hz, 16Amp | |||

| CVT / Stabilizers | If the voltage is unstable then use CVT/Stabilizer to avoid damage | |||

| Working Pressure | 2 to 6 bars (Air Compressor required 1Hp 50Ltr) | |||

❑ Ultrasonic spot welders are used for small spot welds to the fabric.

❑ The fabric can be easily moved on the table.

❑ A foot-operated switch gives starting signals.

❑ Different welding stitching patterns are available.

❑ High productivity and no smoke or fumes produced.

❑ Easy to operate.

❑ High accuracy.

❑ Pressure regulation.

❑ Speed control.

❑ Low noise level.

❑ Ultrasonic welded seam is more fine and neat.

Application List Of Spot Welding Machine

❑ Bandage

❑ Garment Accessories

❑ Lanyard

❑ Loop Handle

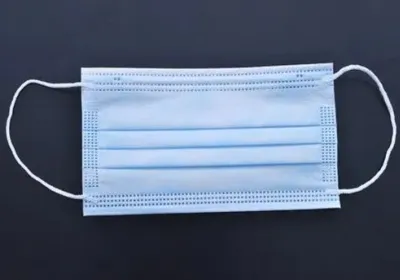

❑ Mask

❑ N-95 Mask

❑ Non-woven Fabric Mask

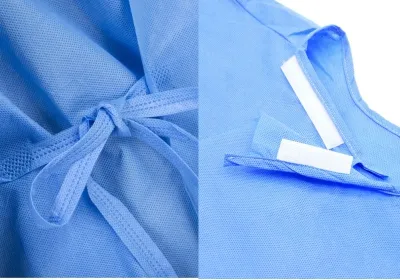

❑ Safety Garments

❑ Surgical Gown Tie Knot

❑ Surgical Sector

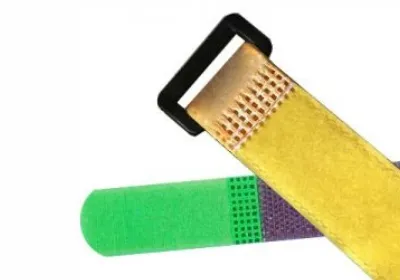

❑ Velcro

Bandage

Garment Accessories

Lanyard

Loop Handle

Mask

N-95 Mask

Non-woven Fabric Mask

Safety Garments

Surgical Gown Tie Knot

Surgical Sector

Velcro