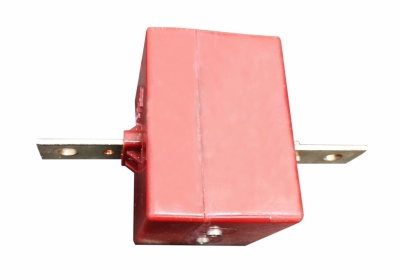

ULTRAAUTOSONIC innovated the Ultrasonic Generator. The ultrasonic generator is a device that converts utility power into a corresponding high-frequency alternating current of a transducer to drive a transducer and is an important component of a high-power ultrasonic system. The ultrasonic generator generates a signal of a specific frequency, which may be a sinusoidal signal or a pulsed signal. This specific frequency is the frequency at which the transducer operates. Ultrasonic equipment generally uses ultrasonic waves of 20 kHz to several MHz.

✔ ULTRA UG 15-2600

✔ ULTRA UG 20-1000

✔ ULTRA UG 20-1200

✔ ULTRA UG 20-1500

✔ ULTRA UG 20-1800

✔ ULTRA UG 20-2000

✔ ULTRA UG 30-600

✔ ULTRA UG 40-500

| Frequency (kHz) | 15 | 20 | 30 | 40 |

|---|---|---|---|---|

| Power (Watt) | 2600 | 1000/1200/1500/1800/2000 | 600 | 500 |

| Horn | Design as per the customized application | |||

| Actual Weight | Approx. 20 kg | |||

| Actual Size (L x W x H) | Approx. (483 X 458 X 238) mm | |||

| Packaging Type and Size | Corrugated Box and Approx. Size (585 X 560 X 336) mm | |||

| Operational Requirement | ||||

| Input Power Supply | AC 230V 50/60Hz, 16Amp | |||

| CVT / Stabilizers | If the voltage is unstable then use CVT/Stabilizer to avoid damage | |||

❑ Digital Display and Controls.

❑ Frequency fine-tuning: The frequency is adjusted so that the ultrasonic generator always works at its optimum state.

❑ Automatic follow-up: Once the device has been initially set up, it can be operated continuously without the need to adjust the generator.

❑ System protection: When the system works in an unsuitable operating environment, the generator will stop working and display an alarm to protect the device from damage.

❑ Amplitude adjustment: The amplitude can be increased or decreased instantaneously during the working process.

❑ The system has Control Mode and Continues Mode.

❑ The conversion efficiency is high.

❑ The ultrasonic generator creates a signal of a specific frequency.

❑ The perfect ultrasonic generator mainly provides feedback signals in the two aspects of output power & frequency tracking.

❑ The efficiency is maximized.

❑ The amplitude setting range is 0% to 100% divided into four stages.

❑ Reduced Thermal Damage.

❑ Low Maintenance.

❑ Fast Processing.

Generator Application List

❑ Bhakarwadi

❑ Bread

❑ Chocolate Bar

❑ Meat

❑ Ice-cream

❑ Kaju Katli

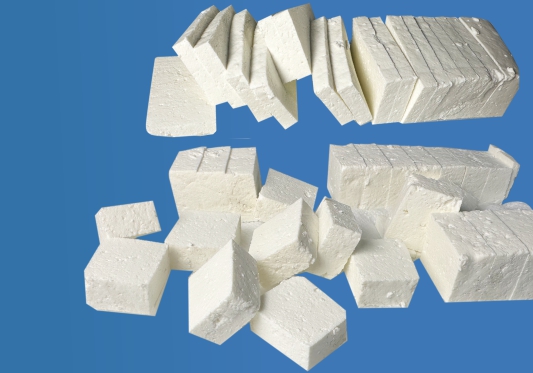

❑ Paneer

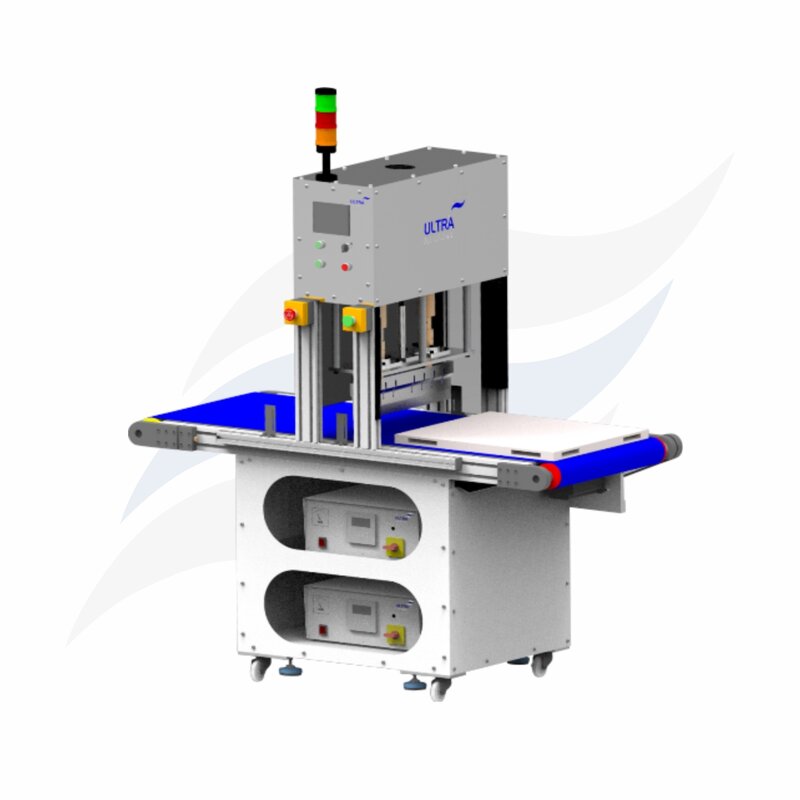

Ultrasonic Plastic Welding Machine

❑ Horn Fixture

❑ Filter Bag

❑ Tetra Packing

❑ Stationary Item

❑ Aerospace Industry

❑ Asthma Inhaler

Ultrasonic Plastic Welding Hand Gun

❑ Cooler

❑ Plastic Knob

❑ Logo

❑ Bumper

❑ Plastic Toys

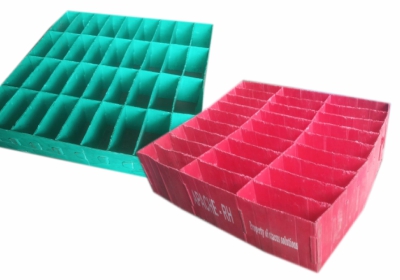

PP Box Welding Machine

❑ Automotive Sector PP Box

❑ Pharmaceutical Storage

PP Box Hand Gun

Ultrasonic Sewing Machine

❑ Surgical Gown

❑ Non-woven Bag

❑ Watch Belt

❑ PP woven Bag

Ultrasonic Spot Welding Machine

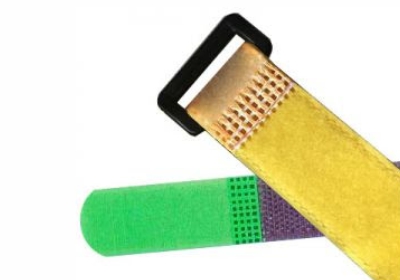

❑ Velcro

❑ Protective Clothing

❑ Garments Accessories

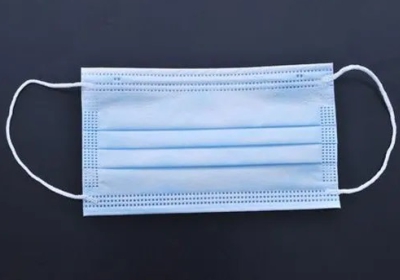

❑ Mask

❑ N 95 Mask

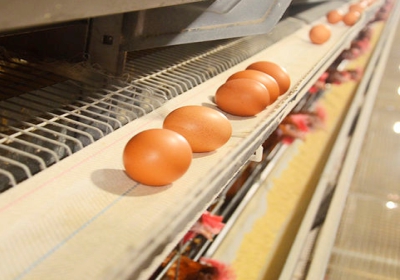

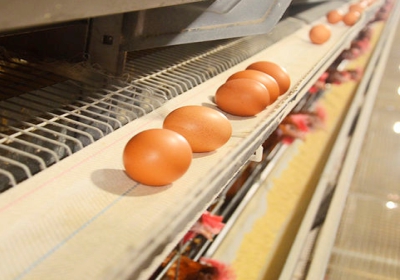

Poultry Manure Belt Welder

❑ H-Layer Battery Cages

❑ Conveyor Belt

❑ Poultry Manure Belt

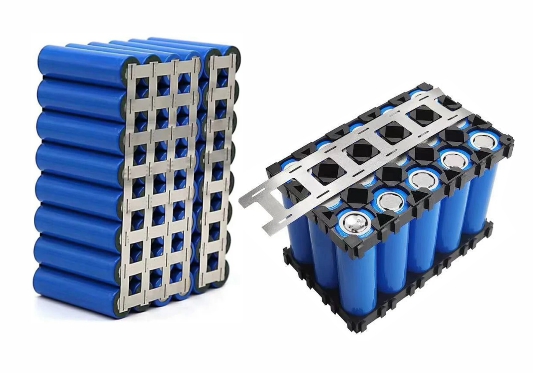

Metal Welding Machine

❑ Battery

❑ Metal Welding

Probe Sonicator

❑ Wax

❑ Beer / Wine

❑ Flower Oil

❑ Herbal Extract

❑ Omega 3

❑ Paint Colour

❑ Perfumes

❑ Pesticide Industry

Flow Cell Reactor

❑ Cornstarch

❑ Chocolate Emulsion

❑ Liquid Syrup

Bhakarwadi

Bread

Chocolate Bar

Meat

Ice-cream

Kaju Katli

Paneer

Horn Fixture

Filter Bag

Tetra Packing

Aerospace Industry

Asthma Inhaler

Cooler

Plastic Knob

Logo

Bumper

Plastic Toys

Automotive Sector PP Box

Pharmaceutical Storage

Surgical Gown

Non-woven Bag

Watch Belt

PP woven Bag

Velcro

Protective Clothing

Garments Accessories

Mask

N 95 Mask

H-Layer Battery Cages

Poultry Manure Belt

Battery

Metal Welding

Wax

Beer / Wine

Flower Oil

Herbal Extract

Omega 3

Paint Colour

Perfumes

Pesticide Industry

Cornstarch

Chocolate Emulsion

Liquid Syrup