Ultrasonic Technology has proven to be a valuable tool in the electronics and electrical industry, offering non-destructive testing, precision manufacturing, and efficient cleaning capabilities, among other advantages. Its non-contact nature and ability to work with sensitive components make it a preferred choice in many applications within the industry.

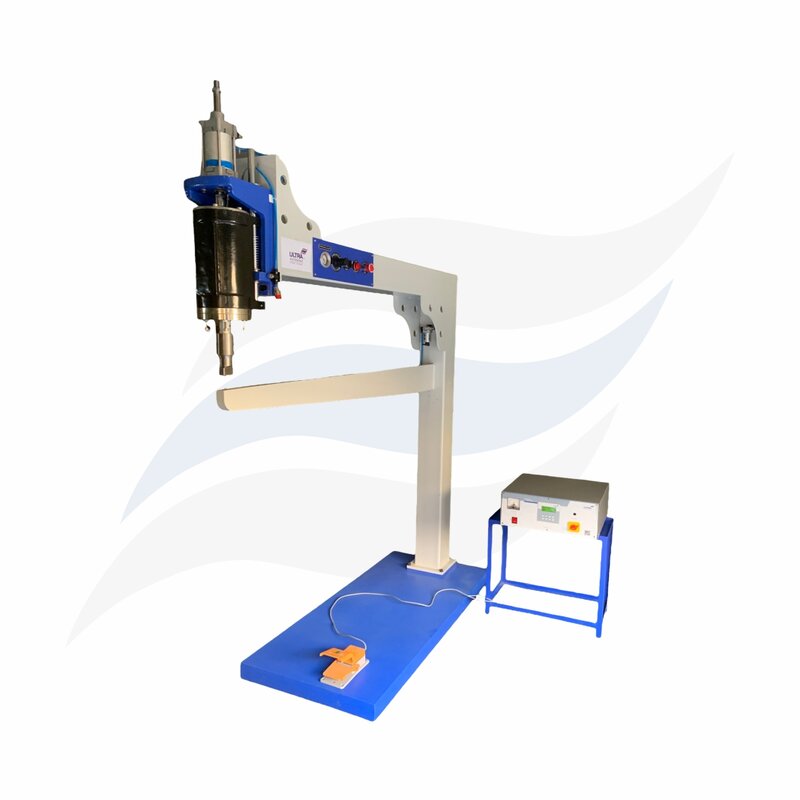

Ultrasonic welding is commonly used for the assembly of various electronic components such as connectors, switches, sensors, and integrated circuits. It allows for precise and reliable joining of plastic parts without the need for adhesives or additional fasteners.

Ultrasonic welding is used to secure wires and cables to connectors and terminals, creating strong and durable electrical connections. This method ensures efficient and consistent bonding, minimizing the risk of loose connections or signal loss.

Ultrasonic plastic welding is utilized in the assembly of batteries, including lithium-ion batteries commonly found in consumer electronics and electric vehicles. It enables the secure attachment of battery components, such as cell holders, covers, and terminals, ensuring proper electrical conductivity and structural integrity.

Many electronic devices require protective enclosures to house their internal components. Ultrasonic welding is employed to join plastic enclosure parts together, providing a sealed and robust housing. This method is particularly useful in manufacturing devices such as smartphones, tablets, computer peripherals, and electrical control panels

Ultrasonic welding is used to encapsulate sensitive electronic sensors or modules with protective plastic housings. This process ensures water and dust resistance, enhancing the durability and reliability of the sensors, which are often used in automotive, industrial, and consumer electronics applications.

Ultrasonic welding can be utilized to mount components on PCBs. It allows for efficient and precise attachment of components such as connectors, capacitors, resistors, and integrated circuits. The process helps reduce production time and offers strong electrical connections.

Ultrasonic welding is employed in the assembly of LCD and LED displays, securing plastic frames, bezels, or backlights. The process provides a high-strength bond while maintaining the optical clarity of the display.

Ultrasonic fabric sealing is commonly used to attach cables and wires to connectors or other components in the electronics industry. It provides a secure and reliable electrical connection by using high-frequency vibrations to generate localized heat and bond the materials together. This technique ensures efficient and consistent assembly of cable harnesses.

In the manufacturing of electronic devices, ultrasonic fabric sealing is employed to seal enclosures, such as plastic or metal housings. By creating a strong bond between the mating surfaces, ultrasonic welding ensures that the enclosure is effectively sealed against moisture, dust, and other contaminants, providing protection to the internal electronic components

Ultrasonic fabric sealing is used to bond various electronic components together. For example, it can be utilized to attach circuit boards to metal or plastic frames, secure displays or touchscreens onto electronic devices, or bond sensors, connectors, and other components onto PCBs (Printed Circuit Boards). This method offers a reliable and efficient way to assemble electronic devices.

Ultrasonic fabric sealing is employed in the packaging of electronic components and devices. It enables the creation of airtight and moisture-proof seals for packaging materials such as plastic films, blister packs, or pouches. By using ultrasonic energy to generate heat and pressure, the packaging materials are fused together, ensuring product integrity and protection during transportation and storage.

Ultrasonic fabric sealing is utilized in the production of various sensors used in the electronics industry. For instance, it can be employed to bond piezoelectric elements or transducers to the sensor housing, ensuring a reliable and robust connection. Ultrasonic welding is particularly advantageous for delicate sensors where traditional heat-based bonding methods may damage sensitive components.

Ultrasonic welding is used to assemble plastic enclosures for electronic devices such as control panels, power supplies, and junction boxes. It provides a strong and durable bond between the different parts of the enclosure, ensuring protection against dust, moisture, and other environmental factors.

Ultrasonic welding is utilized to join wires and cables in the production of electrical harnesses. It offers a quick and efficient method for creating reliable connections between conductors without the need for additional connectors or soldering.

Ultrasonic welding is employed in the assembly of batteries used in various electronic devices. It enables the secure attachment of battery components, such as terminals and connectors, ensuring proper electrical contact and overall battery integrity.

In the electronics industry, ultrasonic welding is often utilized to assemble sensors and actuators. These components require precise alignment and bonding, which can be achieved effectively with ultrasonic welding. It helps create hermetic seals and maintain the integrity of sensitive electronic components.

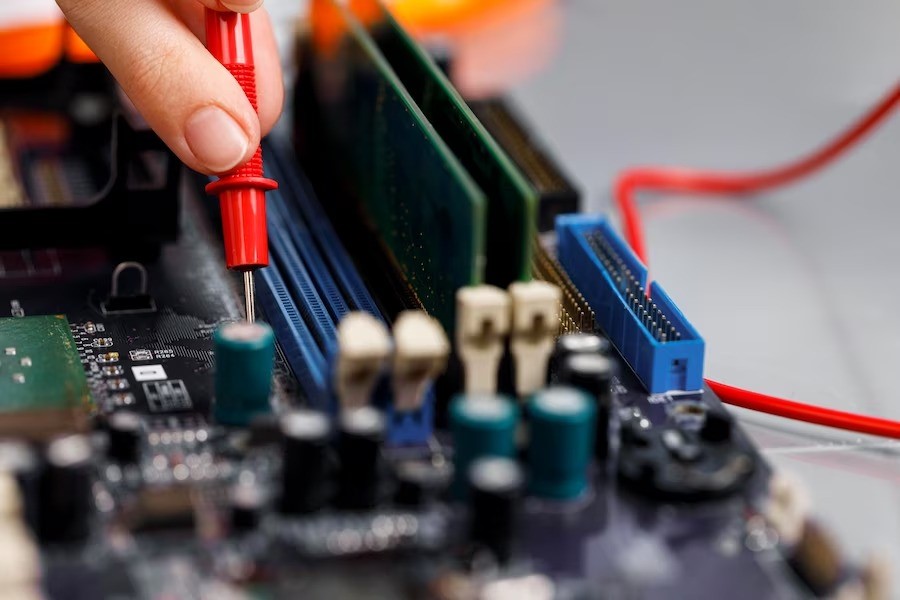

Ultrasonic welding is employed in the PCB manufacturing process for applications such as attaching connectors, mounting components, and bonding layers. It provides a fast and reliable method for creating robust connections without the need for additional adhesives or soldering.

Ultrasonic welding is used to join plastic components of electrical connectors. It ensures proper electrical conductivity and mechanical strength while minimizing the risk of damage to delicate connector pins.

Ultrasonic welding is employed to create seals and bonds in electrical insulation materials. It helps in the production of insulating components for electrical switches, connectors, and other devices, ensuring safety and reliability.

Ultrasonic metal welding is commonly used in wire bonding processes, where fine wires (usually gold or aluminum) are bonded to semiconductor chips and lead frames in integrated circuits (ICs) and microelectronic devices. This technique ensures a strong and stable connection between the wire and the contact pads on the chip.

Ultrasonic metal welding is employed in the assembly of batteries, especially in lithium-ion battery production. It is used to weld the metal tabs or connectors of battery cells, ensuring low electrical resistance and a secure connection between the battery components.

Connectors are crucial components in electronic devices, providing electrical and mechanical connections between various parts. Ultrasonic metal welding is utilized in assembling connectors, ensuring reliable connections without the need for additional soldering or brazing.

In the production of sensors, ultrasonic metal welding is used to bond delicate components, such as piezoelectric elements and microelectromechanical systems (MEMS), with high precision and minimal heat generation.

Ultrasonic metal welding is employed to assemble the various parts of RFID (Radio Frequency Identification) tags, including the antenna and chip bonding, ensuring a robust and reliable connection for effective data transmission.

In certain cases, ultrasonic metal welding can be used to join metal components on PCBs, offering an alternative to traditional soldering methods.

Ultrasonic metal welding is utilized in the assembly of miniature electronic components and packages, especially in microelectronics and miniaturized devices.

The electronics industry often requires hermetic sealing to protect sensitive components from environmental factors such as moisture and contaminants. Ultrasonic metal welding can achieve effective hermetic seals between metal parts.

Ultrasonic metal welding is used in LED (Light Emitting Diode) packaging to create reliable connections between the LED chips and their substrates or lead frames.

In flexible electronics and wearable devices, ultrasonic metal welding can be employed to join thin metal traces on flexible substrates without damaging the delicate components.

Battery Manufacturing

Bonding electronic components

Cable and wire harness assembly

Printed Circuit Board (PCB) Assembly