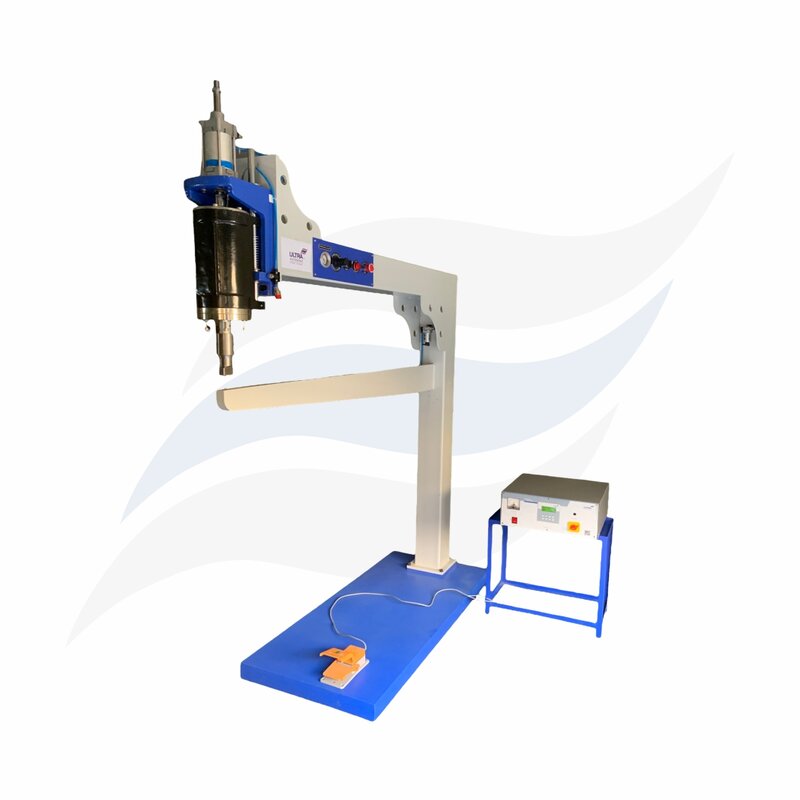

Ultrasonic Technology plays a significant role in the packaging industry by enabling efficient, cost-effective, and environmentally friendly manufacturing processes.These sound waves are used to create mechanical vibrations that can be harnessed for joining, cutting, sealing, and welding different packaging materials without the need for additional adhesives

Ultrasonic welding is commonly used for sealing and closing various types of plastic packaging, including bags, pouches, blister packs, and clamshell packaging. It provides a reliable and secure seal, ensuring product integrity and preventing contamination.

Ultrasonic welding is utilized for assembling plastic components in packaging, such as attaching handles, brackets, or clips. It enables fast and efficient assembly without the need for additional adhesives or fasteners.

Ultrasonic welding can create tamper-evident seals on packaging, ensuring product safety and preventing unauthorized access. These seals are designed to break or show visible signs of tampering when the package is opened.

Packaging for liquid products often requires spouts or dispensing features. Ultrasonic welding can be used to attach spouts to flexible packaging materials, creating a secure and leak-proof connection.

Blister packs, commonly used in pharmaceutical and consumer goods packaging, require precise sealing. Ultrasonic welding can bond the plastic blister to the backing card, providing a secure and visually appealing package.

Ultrasonic welding is utilized in the production of plastic tubes, such as those used for toothpaste, creams, or ointments. It ensures a strong and uniform seal along the length of the tube, preventing leakage and maintaining product freshness.

In certain packaging applications, filters or membranes need to be securely bonded to plastic components. Ultrasonic welding offers a clean and precise method for joining these components, ensuring a strong and reliable bond.

Ultrasonic welding is used in the assembly of microfluidic devices, which are extensively used in medical and diagnostic packaging. It enables the bonding of intricate plastic channels and components, ensuring precise fluid control.

Ultrasonic fabric sealing is commonly used for sealing bags and pouches made of various materials, including plastic films, laminates, and non-woven fabrics. It provides strong, consistent seals that are airtight and watertight, ensuring product freshness and preventing contamination. This is particularly important for packaging food, pharmaceuticals, and other perishable items.

Ultrasonic sealing is ideal for blister packaging, where a plastic blister is sealed to a paperboard or plastic backing. The ultrasonic energy creates a hermetic seal, protecting the packaged product from moisture, dust, and tampering. It is commonly used for packaging small consumer goods, electronics, and pharmaceutical products.

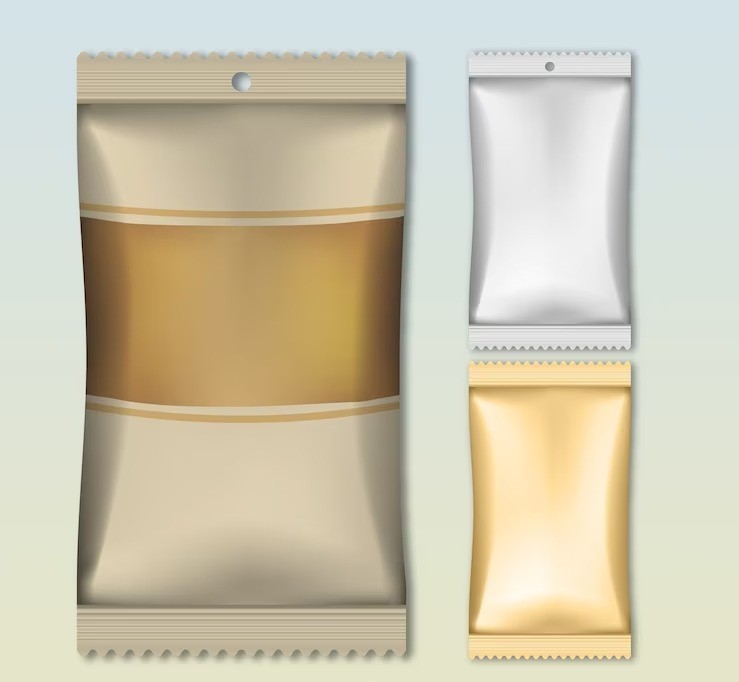

Sachets are small, sealed packets used for packaging powdered or liquid products such as condiments, sauces, shampoo, or single-use cosmetic products. Ultrasonic sealing ensures leak-proof seals, preventing any spillage or contamination. It offers high-speed sealing for sachet production lines, improving productivity and reducing production costs.

Stand-up pouches have gained popularity in the packaging industry due to their convenience and shelf appeal. Ultrasonic sealing is used to create the bottom seal of stand-up pouches, providing excellent strength and integrity. The technology enables efficient sealing of the pouches, even with complex shapes or multiple layers of materials.

Non-woven fabrics are widely used in packaging applications such as tote bags, gift bags, and promotional bags. Ultrasonic fabric sealing offers a clean and precise method for joining non-woven fabric panels, creating strong and durable seams. It eliminates the need for stitching or adhesives, resulting in faster production and enhanced aesthetics.

Ultrasonic sealing can create tamper-evident seals on packaging, providing a visual indication if the package has been opened or tampered with. This is crucial for ensuring product safety and preventing unauthorized access to the packaged contents. Tamper-evident seals are commonly used in pharmaceuticals, cosmetics, and high-value consumer goods.

Ultrasonic welding is commonly used to assemble and seal PP boxes and containers. It creates strong and reliable seals by using high-frequency mechanical vibrations to melt and fuse the PP materials together. This method ensures airtight and watertight seals, making it suitable for various industries such as food and beverage, pharmaceuticals, and consumer goods.

Blister packs are widely used for packaging small consumer products, medicines, and medical devices. Ultrasonic welding is employed to seal the PP blister cavities to the backing cards or foil lids. This technique provides secure and tamper-evident packaging, ensuring the integrity of the enclosed products.

Ultrasonic welding can also be applied to flexible packaging materials made of PP, such as pouches, bags, and sachets. It is used to create strong seals along the edges, ensuring product containment and freshness. This method eliminates the need for adhesives or heat sealing, resulting in faster production speeds and improved packaging integrity.

Ultrasonic welding is effective in creating tamper-proof seals on PP packaging. By melting the PP materials together, it forms a strong bond that is difficult to break without leaving visible signs of tampering. This feature is particularly important for pharmaceuticals, sensitive electronic components, and high-value consumer products.

Ultrasonic welding enables customization in the packaging industry. It allows for the creation of unique shapes and sizes of PP boxes and containers by joining multiple components together. This flexibility makes it possible to design packaging solutions tailored to specific products or branding requirements.

Ultrasonic PP box welding is considered an environmentally friendly packaging solution. It doesn't require the use of additional adhesives, solvents, or heat, reducing the consumption of energy and resources. Additionally, the resulting seals are strong and durable, improving the overall sustainability of the packaging.

Box and Container Manufacturing

Packaging Assembly

Sachet Packaging

Tamper Evident Seals