Ultrasonic Technology in the paints and coatings industry offers numerous advantages, including improved product quality, reduced waste, increased efficiency, and enhanced overall performance of the coatings. It is considered a valuable tool for researchers, manufacturers, and applicators looking to optimize their processes and achieve better results.

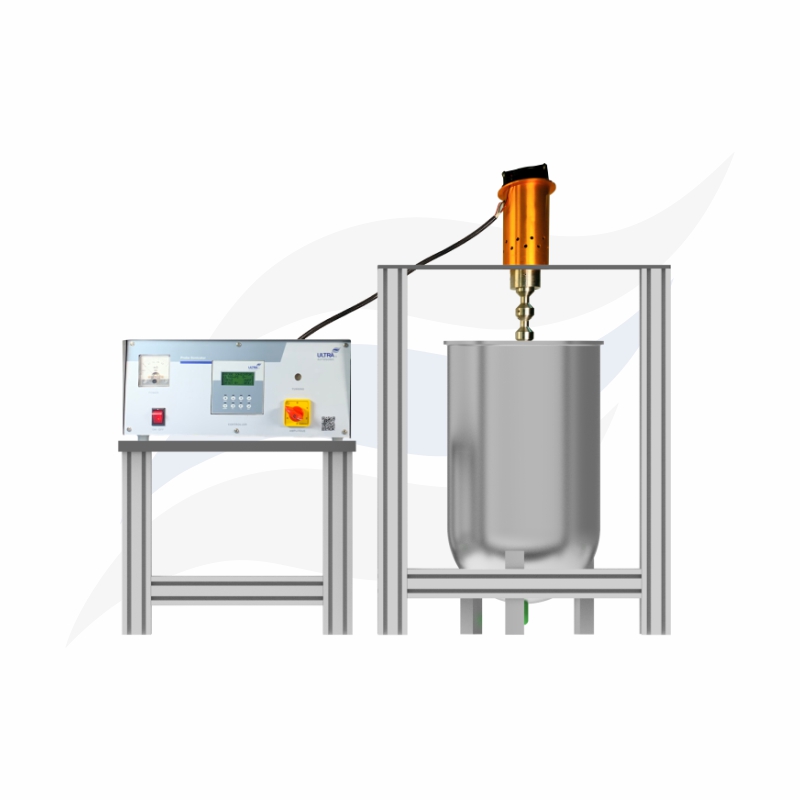

Ultrasonic sonication is an effective technique for dispersing pigments into paint formulations. The high-frequency ultrasound waves create cavitation bubbles in the liquid, which collapse violently upon reaching a certain size. These collapses generate intense shear forces, breaking down pigment agglomerates and achieving uniform dispersion. This process results in better color development, improved stability, and enhanced overall performance of the paint.

Ultrasonic sonication can be employed to reduce the particle size of solid additives, such as fillers, extenders, or nanomaterials, in paint formulations. By subjecting the suspension to intense acoustic cavitation, the high shear forces generated during bubble collapse break down larger particles into smaller ones. This reduction in particle size can lead to improved properties like increased hiding power, enhanced mechanical strength, and smoother surface finish of the paint or coating.

Ultrasonic sonication is also used for efficient mixing and emulsification of paint components. By applying high-intensity ultrasound, it is possible to create fine emulsions or achieve homogenization of different liquid phases. This can be beneficial when formulating water-based paints, solvent-based paints, or other specialty coatings where achieving a stable and uniform mixture is crucial.

During the manufacturing process of paints and coatings, air bubbles or other entrapped gases can lead to surface defects or reduced coating performance. Ultrasonic sonication can aid in degassing and removing these unwanted bubbles by applying acoustic energy that promotes bubble nucleation and subsequent release of gas. This helps to improve the overall quality and appearance of the final coating.

Ultrasonic cleaning is a common application in the paints and coatings industry, particularly for removing contaminants from various substrates. This technique uses ultrasonic waves to create high-frequency pressure waves in a liquid bath, producing microscopic bubbles that implode near the surface of the object being cleaned. The implosions generate intense local agitation, dislodging and removing dirt, grease, oils, and other residues. This process ensures proper surface preparation before applying the paint or coating, resulting in improved adhesion and durability.

Degassing and bubble removal

Mixing and emulsification